Jimmy Enters the 20th Century

Better Test Stands, Better Data

|

Dawn of the

Electronic Age! Jimmy Enters the 20th Century Better Test Stands, Better Data |

(click on image to view

photo)

|

Electronic test stand A:

20kg load cell Test stand using 20kg load cell from Aerocon Systems. Mechanical design and electronics by Steve Ghioto, wood base and red paint by Jimmy. Here it is holding a Dr. Rocket 38/240 casing I often use for propellant tests. Yes. That wood base is from the old wooden beam test stand which was broken last year by CATO. PVC G-motor managed to break 2 layers of 3/4 inch oak plywood. I made another beam. On the first test, another CATO broke it too! |

|

20kg stand the with the

motor mount removed.

It shows the smash plate plunger, which is intended to prevent

damage to the load cell

from overpressure. We have already tested it with a CATO (someone

else's motor) and

it held up OK. Clearance underneath the load cell is exaggerated by the reflection in the still-new, still-clean paint job. A few tests will fix that. |

|

Test Stand B: 500 lb load cell Similar design but larger. Seen here with 54mm 3-grain Loki casing. Ok, so I haven't painted this one yet. Too many other irons to fry. But I am keeping it clean now! Unsightly corrosion attests to the caustic nature of the propellant by-products. |

|

Test Stand B: Top View Shows more detail of the smash plate and load cell mounting. Some have expressed reservations about the PVC motor mount, but in over 50 tests it has worked just fine. |

|

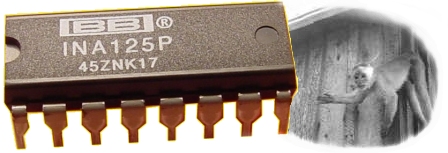

INA125 Amplifier - I've

learned to build that pesky little amp myself! And documented my

erratic progress. Click Here for several pages of boring construction details, interspersed with feeble attempts at humor and some pictures. |

|

Static Tests performed with

these stands, videos and spreadsheet analyses. |

|

Flab-O-Graphter - Lobotomized bath scale makes a fairly good test stand. |