This is so easy it is hard. Just make the uninhibited grain and wrap it with aluminum foil duct tape. Not the cheap plastic type Red Green uses for everything but taping ducts, but the kind that is heavy aluminum foil with a plastic backing and a good layer of adhesive.

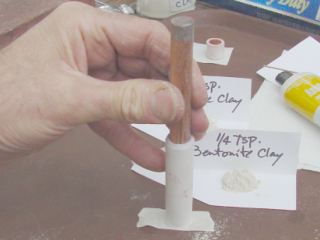

Cut a piece of tape long enough to go around the grain once, plus a little more for insurance. Peel the backing from the tape and stick it somewhere at the ready. Remove the mold liner from the uninhibited grain, and wrap it with tape. This makes one long inhibited grain. It would be a progressive burning grain, which is sometimes desirable but in this case not.

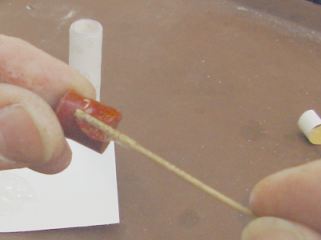

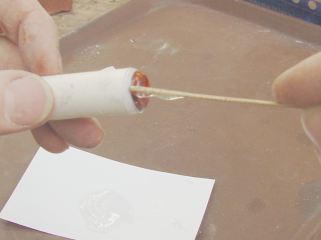

So we will make it a simple but dramatic change to this progressive burning grain that will turn it into a relatively-neutral burning Bates grain. Or two. We will cut it in half.

Place the grain on a cutting board. Take a large, sharp knife and place the edge right exactly in the middle. Measure if you have to. Roll the knife over the grain back and forth until it chops through.

Hopefully, the grain was not crushed by this action. Usually they handle it just fine, and once you have cut through the tape, the grain snaps easily. If the cut is a bit irregular, no big deal. Use it anyway.

The nozzle throat will need to be smaller. The foil tape inhibits the outside of the grain from burning, so much less propellant will be ignited at any one time. So if the 3/16ths inch drill is used, the Kn ratio will be far too low and the motor will not build enough pressure to have a stable, efficient burn.

So another nozzle drill is made, this one using a 1/8th inch (3mm) drill bit.

Make the tube, pound the plug, drill the throat, and flare it as previously described. Then these two little grains are inserted in the case and the header glued in. The result is a tiny motor with a "neutral" burn profile. It delivers a moderate, even thrust from the beginning of the burn to the end and everyone is happy! Well, if the model is light it might be happy, but if it is on the heavy side, use the uninhibited grain. It is good for kicking a heavy airframe off the pad and getting up to stable airspeed quickly. The Bates grain is good for long, even thrust to get light models to good altitude.

But why bother with making a Bates grain motor? It isn't much more trouble, but a little. And it delivers lower thrust, although for a longer time. What's the big deal?

The big deal is "flat burn profile." Sounds awfully boring, and in a way, it is. It makes the burning profile of the grains relatively neutral, not varying a huge amount from the beginning to the end of the burn. This allows about twice the amount of propeellant to be burned in a given case and nozzle design than would be possible when using an uninhibited grain.

But you will say "the model rocket motor case is full! It can't hold any more propellant." Therein lies the ru b with these small cases with a standardized geometry. But if you are willing to diverge from the standard a bit, say by making your motor tubes 1.5 inches longer and putting 4 tiny Bates grains in them, then the motor would jump from a high-end C motor to a high-end D or low-end E motor.

The idea is a clever one. Propellant for a given motor is made into several "slugs" which are about 1.6 times as long as their diameter. They are inhibited from burning on the outer surface by some fire-retardant substance. Thus the inner core can burn, and both ends can burn.

As the core burns, it gets bigger. As it gets bigger, the burning surface increases. As the burning surface increases, more hot propellant gas is produced, and pressure and thrust tend to increase. This is called a "progressive burn" as it progresses from a lower thrust to a higher thrust.

But the ends of each grain also burn, shortening the grain as the burn progresses. So as this burning core gets larger in diameter, it also becomes shorter, so there is less core surface area burning. And as the core gets larger, the ends have less surface to burn.

The net effect of these ofsetting tendencies is a burn profile that is "progressive-regressive." It is mildly progressive during the first part of the burn, mildly regressive toward the end of the burn. Plotted on a graph, it shows a gentle curve upward, then an equally gentle curve downward.

Why do we want this? Well there are two major reasons.

Reason 1: High Pressure = High Efficiency

The amount of thrust generated by a propellant is related to the pressure under which it is burned. Higher pressures extract more of the energy of a given propellant in the form of thrust. The difference can be dramatic. High-pressure motors generate much more kick than low-pressure motors of the same type.

Progressive and regressive-burning motors will be less efficient at the low-pressure end of the burn. Simple core-burning motors, being progressive in nature, are inefficient at the beginning of the burn. They will be slow in getting a rocket off the launch pad, and thus are not often preferred among motor builders.

Uninhibited grains are moderately regressive. They generate maximum pressure at the beginning of the burn, then taper off. They are very good at getting an airframe off the pad, but are not particularly efficient toward the end of the burn.

The nearly-neutral burn of the Bates grain allows the motor to burn

at nearly the same pressure during the whole burn, thus it can be designed

to burn at high pressure the whole way. The increase in performance

can be substantial.

2. Stable burn/Case limitations

A motor case must be designed to contain the maximum amount of pressure that the propellant will generate during the burn. Plus a margin for safety. With a progressive or regressive grain configuration, some of the case capability will be "wasted."

More importantly, with a progressive grain in paper casings it can be difficult to design a casing/nozzle/propellant combination that will work at all. Below a certain pressure, a propellant may burn so inefficiently as to hardly burn at all. It may "chuff" or cough on the launch pad, perhaps jumping a little but not going very far at all. For an outstanding and somewhat embarrasing illustration of this tendency, check out the Shorty pages.

This brings us to the concept of Kn ratio. It is a big one. It is well worth a few minutes or even a few hours' study, as this one principle allows the design of rocket motors that are very likely to work.

Kn is the ratio of the burning surface of propellant to the area of the nozzle throat.

It is closely related to pressure, and thus to thrust. This relationship can be described by an equation known as Vielle's Law, also known as De Saint Robert's Equation.

We have already discussed some of the geometry of propellant grains,

and how that geometry changes during a burn.

Jimmy Yawn

1/10/04

jyawn@sfcc.net